Our world leading solutions

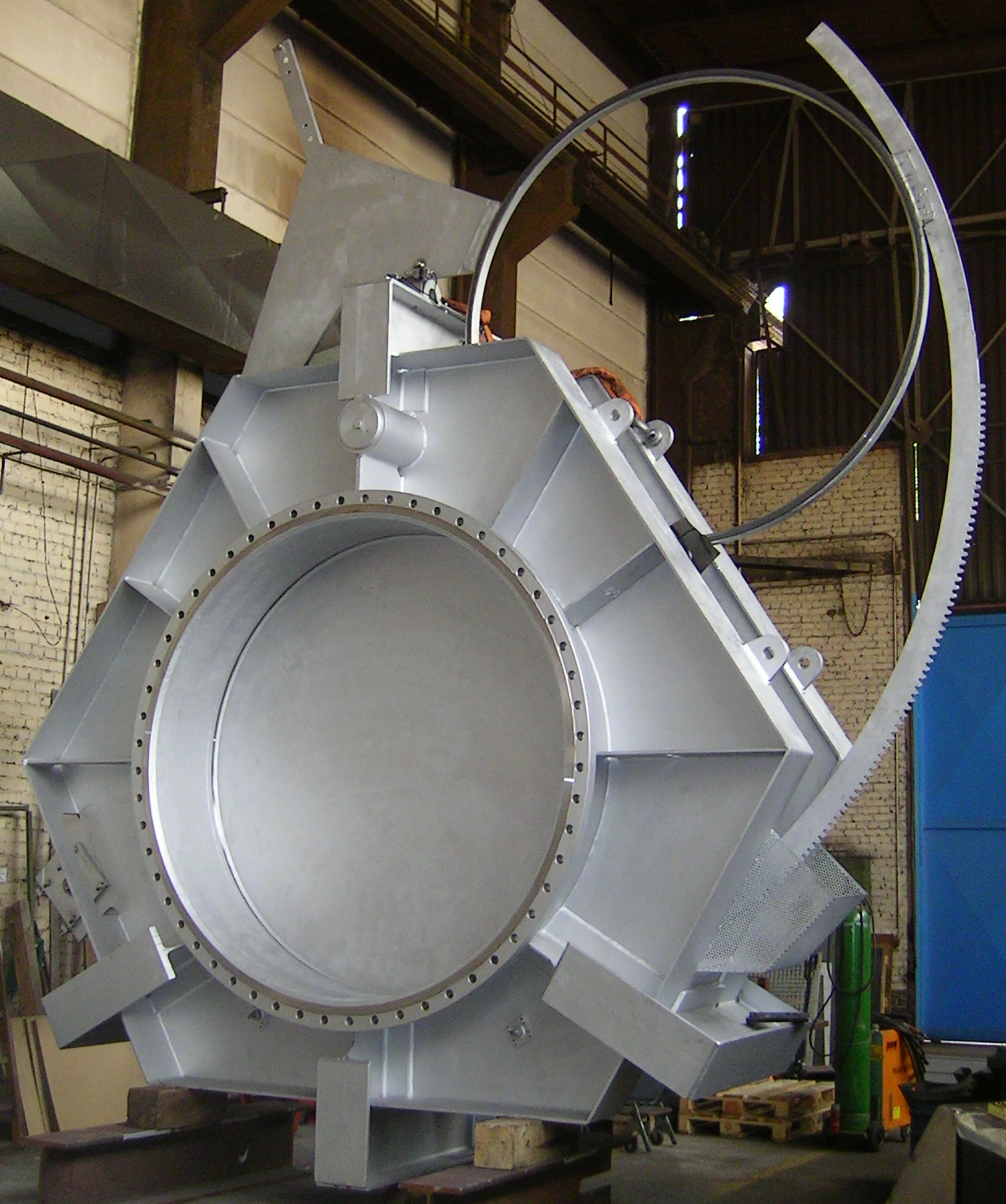

Under our IMI Th Jansen valve line, IMI provide a range of shut-off and control butterfly valves used widely in the world’s harshest manufacturing environments. Renowned for their high quality, operational safety, low maintenance requirements and long-life cycle they offer excellent performance in hot blast furnaces, coke ovens, gas recovery systems and air separation plants.

Specialised valves for major industries

Iron and steel

IMI Th Jansen air isolation and regulation valves are used widely in iron and steel production facilities. These valve solutions are used in hot and toxic gas applications and gaseous and/or toxic media with high dust content. IMI also provide valves for gas recovery systems and ignition systems.

Petrochemical

With decades of experience supplying high-quality bespoke valve solutions for the petrochemical industry, IMI create technologies around the operating conditions of each individual plant. Our IMI Th Jansen line of transfer line and decoking live valves are widely used in ethylene plants, providing control valves for differential pressures and tank bottom valves for liquid and gaseous media.

Water and power

Clean drinking water and energy are vital to the health and well-being of a growing global population. IMI have extensive experience in developing valve technology for the power sector and provide butterfly valves for both nuclear and conventional facilities. In the water sector, IMI develop gate valves for isolation purposes and special systems to protect against corrosion.

Aftersales support

IMI’s global aftersales support team provides expert field service, repairs, spare parts, upgrades as well as long-term service contracts. We ensure that processes function safely and efficiently for the complete life cycle of your facility.

Services